All products

Helium is one of the smallest NVIDIA® Jetson™-based embedded systems on the market. Despite its compact size, it delivers impressive computing power and is designed for use in extreme environments. Thanks to its IP67 rating, it is waterproof, dustproof, and shock-resistant, ensuring reliable operation even under the harshest conditions.

The Vapor Phase Two offers development engineers as well as small to

medium sized prototyping service providers one of the most gentle

soldering processes in the industry. Compared to the Vapor Phase One it has a bigger PCB solder area.

Liquid Galden© LS230 from the company SOLVAY for vapor phase soldering.

The boiling point is 230 °C and is therefore ideally suited for SMT

soldering with the common solder pastes.

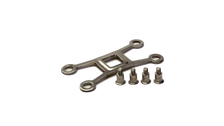

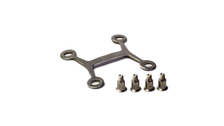

You need the right mounting material for your Jetson Nano project or product? We deliver a whole set with one Leaf spring and four screws - Recommended by NVIDIA®.

You need the right mounting material for your Jetson TX2 NX project or product? We deliver a whole set with one Leaf spring and four screws, perfect for mounting your heatsink - Recommended by NVIDIA®.

You need the right mounting material for your Jetson Xavier NX project or product? We deliver a whole set with one Leaf spring and four screws, perfect for mounting your heatsink - Recommended by NVIDIA®.

With the PCB Arts desoldering system for vapor phases you can easily and reproducibly save different components from your already soldered assembly. Ball-grid arrays, connector strips and mechanical elements can be can be desoldered gently and safely.

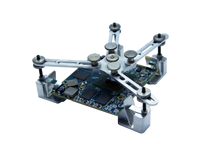

For double-sided soldering in the Vapor Phase One or Two, standoffs facilitate easier handling and contribute to more consistent soldering outcomes.

Connect seamlessly to your Helium via USB-C and unlock a dual-port interface engineered for efficient Jetson development workflows.